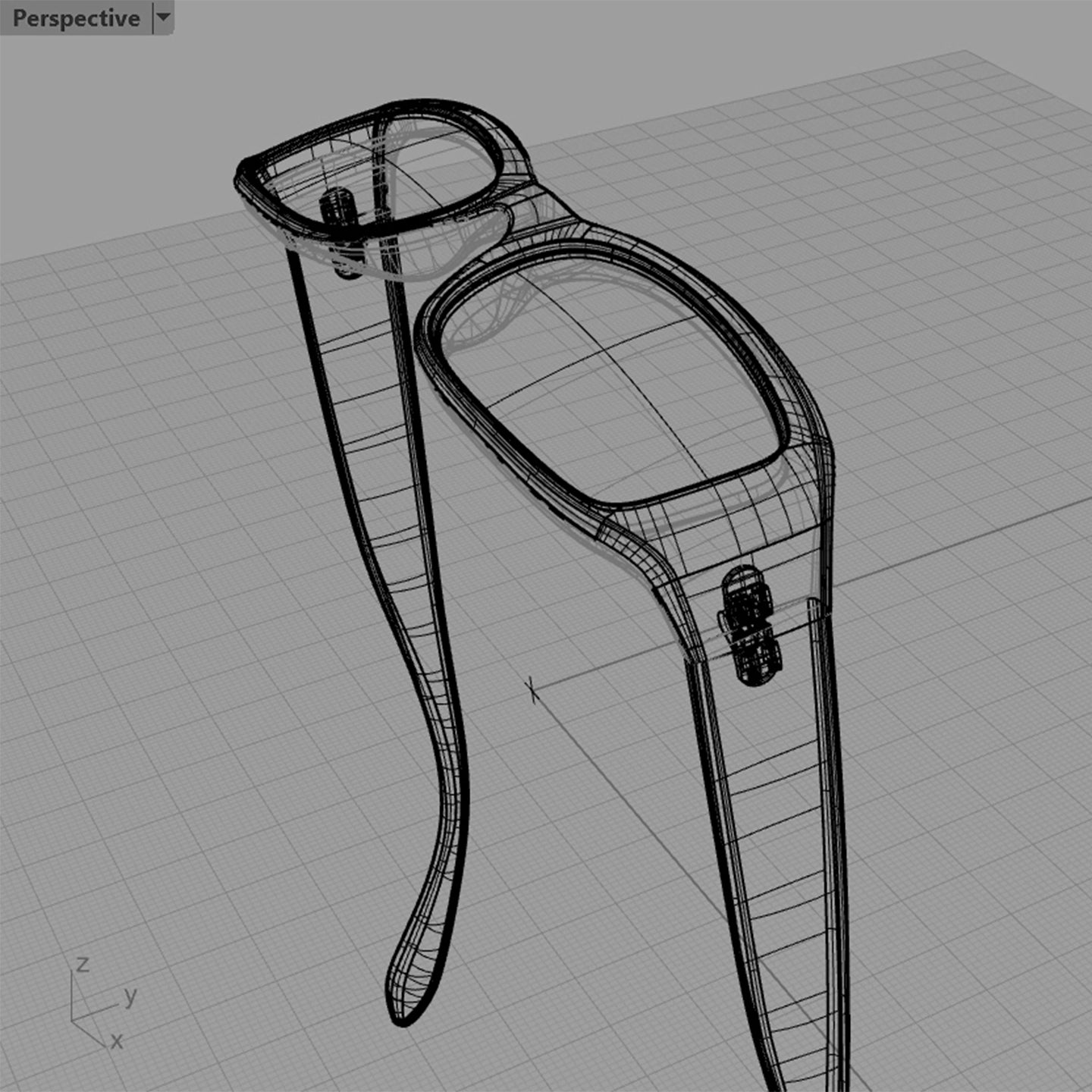

from sketch to sunglass

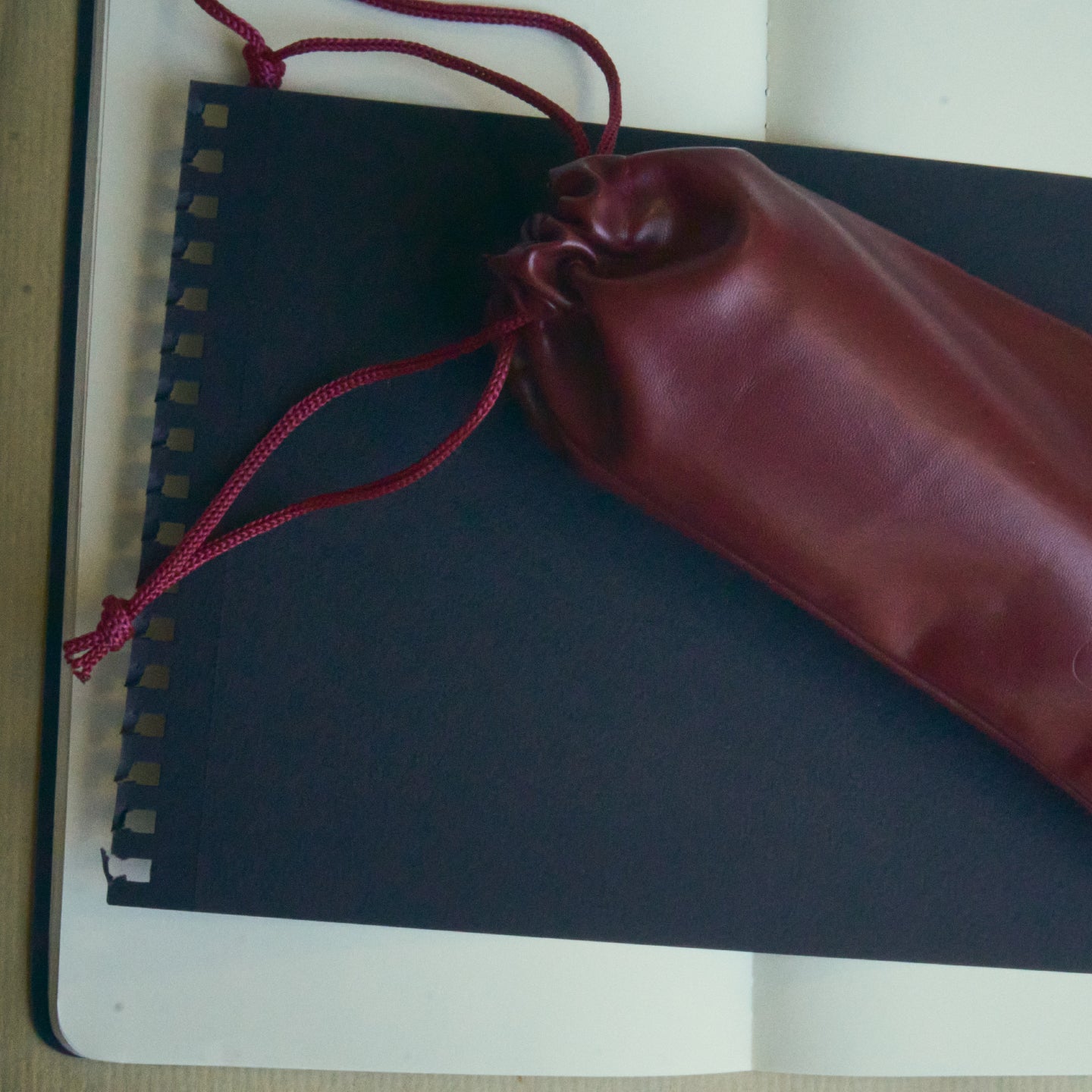

from pencil to prototype... from hand to hand; every frame concept begins as a sketch on paper and ends in the hands of our skilled production team. each design passes through a journey of inspiration, concept ideation, technical drawings, iterative revisions, 3D-printed prototypes, and finally injection-moulded samples where colours, patterns, and surface treatments are perfected. every pair is then hand-assembled, edge-finished, polished, and carefully inspected before being nestled into its pouch and box. throughout this process, we obsess over fit, construction, alignment, comfort and the quality of finish, going to extraordinary lengths to create frames that flatter and endure. months of research, development, fit testing, and refinement culminate in sunglasses that carry the spirit of luxury, yet feel effortless enough for everyday wear.

our mission

just like you, we’re trying to be kinder… to the planet, to each other, and to ourselves. at szade, we start by crafting every pair of our sustainable plastic sunglasses from recycled materials, turning industry waste into frames rather than relying on virgin plastics. sustainability is a journey, and we’re always seeking ways to be gentler, cleaner, more innovative, and more efficient. we hope to eventually extend our sustainable practices and capabilities to our metal collection too as the industry grows and innovates.

our recycled components

each of our sustainable polycarbonate frames is constructed from a blend of pre- and post-consumer plastics and is hand-assembled, polished, and packed for a high-quality finished product. this careful process ensures that our recycled frames are durable, comfortable, and made to the highest standards without compromise.

dotting our 'i's' & crossing our 't's'

the recycled materials we use are sourced from trusted production partners and come with GRS certification, independently auditing the materials and their chain of supply.

breaking the cycle

when your polycarbonate frames have lived their full life, recycle them responsibly. remove any metal components and check that your local facility or unit accepts polycarbonate. our hypoallergenic metal frames should not be placed in polycarbonate recycling streams, and instead deposited to units or facilities that recycle metal components. every recycled pair returned helps close the loop and gives new life to materials.

let's make something clear

our lenses are crafted from premium, drop-ball tested and industry rated polycarbonate for ultimate clarity, impact resistance, and protection. our lenses can be recycled in the same units and facilities as our frames. meeting the highest international safety standards, they ensure shatterproof protection for your eyes. your safety comes first.

how we power our business

our operations team is based in a repurposed chocolate factory in Melbourne, Australia... it’s a space that embodies our ethos of using existing resources to innovate. our distribution partner has been part of the CitySwitch energy efficiency program since 2017, and together we continue to pursue cleaner, more sustainable energy sources, including a 265kWp solar panel array installed in 2020 that powers our business.

it's the little things...

sustainability extends to every corner of our operations:

• minimising paper and cardboard use through careful printing practices and the reuse of packaging.

• reusing materials wherever possible, in line with our unique recycling philosophy.

• recycling e-waste with local organisations.

• recycling as much waste as possible, including composting organic matter for our on-site worm farm.

• increasing energy efficiency via automated lighting, heating, cooling systems, and efficient fixtures.

• using responsibly sourced recycled paper throughout our offices.

a paper trail we're proud of

from cardboard shippers to tags, catalogues, and brand cards, we use recycled paper and cardboard. we avoid single-use plastics, and each frame is wrapped in recycled tissue for protection during packing instead of plastic sleeves.

if you've made it this far...

conscious consumption starts with a conversation

if you’re exploring Szade, we’re here for an open dialogue about consumption in an age of fast fashion and trend-driven overconsumption. Fashion and self-expression drive our work, but we encourage thoughtful shopping:

• Do I want it?

• Do I need it?

• If not, why do I want it?

• How will I wear or style this?

• Does it suit my lifestyle?

from sketch to sunglass

from pencil to prototype... from hand to hand; every frame concept begins as a sketch on paper and ends in the hands of our skilled production team. each design passes through a journey of inspiration, concept ideation, technical drawings, iterative revisions, 3D-printed prototypes, and finally injection-moulded samples where colours, patterns, and surface treatments are perfected. every pair is then hand-assembled, edge-finished, polished, and carefully inspected before being nestled into its pouch and box. throughout this process, we obsess over fit, construction, alignment, comfort and the quality of finish, going to extraordinary lengths to create frames that flatter and endure. months of research, development, fit testing, and refinement culminate in sunglasses that carry the spirit of luxury, yet feel effortless enough for everyday wear.

our mission

just like you, we’re trying to be kinder… to the planet, to each other, and to ourselves. at szade, we start by crafting every pair of our sustainable plastic sunglasses from recycled materials, turning industry waste into frames rather than relying on virgin plastics. sustainability is a journey, and we’re always seeking ways to be gentler, cleaner, more innovative, and more efficient. we hope to eventually extend our sustainable practices and capabilities to our metal collection too as the industry grows and innovates.

our recycled components

each of our sustainable polycarbonate frames is constructed from a blend of pre- and post-consumer plastics and is hand-assembled, polished, and packed for a high-quality finished product. this careful process ensures that our recycled frames are durable, comfortable, and made to the highest standards without compromise.

dotting our 'i's' & crossing our 't's'

the recycled materials we use are sourced from trusted production partners and come with GRS certification, independently auditing the materials and their chain of supply.

breaking the cycle

when your polycarbonate frames have lived their full life, recycle them responsibly. remove any metal components and check that your local facility or unit accepts polycarbonate. our hypoallergenic metal frames should not be placed in polycarbonate recycling streams, and instead deposited to units or facilities that recycle metal components. every recycled pair returned helps close the loop and gives new life to materials.

let's make something clear

our lenses are crafted from premium, drop-ball tested and industry rated polycarbonate for ultimate clarity, impact resistance, and protection. our lenses can be recycled in the same units and facilities as our frames. meeting the highest international safety standards, they ensure shatterproof protection for your eyes. your safety comes first.

how we power our business

our operations team is based in a repurposed chocolate factory in Melbourne, Australia... it’s a space that embodies our ethos of using existing resources to innovate. our distribution partner has been part of the CitySwitch energy efficiency program since 2017, and together we continue to pursue cleaner, more sustainable energy sources, including a 265kWp solar panel array installed in 2020 that powers our business.

it's the little things...

sustainability extends to every corner of our operations:

• minimising paper and cardboard use through careful printing practices and the reuse of packaging.

• reusing materials wherever possible, in line with our unique recycling philosophy.

• recycling e-waste with local organisations.

• recycling as much waste as possible, including composting organic matter for our on-site worm farm.

• increasing energy efficiency via automated lighting, heating, cooling systems, and efficient fixtures.

• using responsibly sourced recycled paper throughout our offices.

a paper trail we're proud of

from cardboard shippers to tags, catalogues, and brand cards, we use recycled paper and cardboard. we avoid single-use plastics, and each frame is wrapped in recycled tissue for protection during packing instead of plastic sleeves.

if you've made it this far...

conscious consumption starts with a conversation

if you’re exploring Szade, we’re here for an open dialogue about consumption in an age of fast fashion and trend-driven overconsumption. Fashion and self-expression drive our work, but we encourage thoughtful shopping:

• Do I want it?

• Do I need it?

• If not, why do I want it?

• How will I wear or style this?

• Does it suit my lifestyle?

Australia

Australia